Removal Residual H2O2 Enzyme

Chemical Name: Removal Residual H2O2 Enzyme

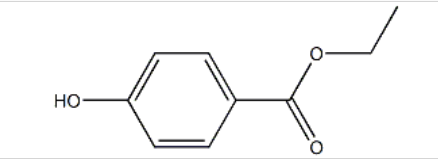

Molecular Formula:C9H10O3

Molecular Weight: 166.1739

Structure:

CAS Number: 9001-05-2

Specification

Appearance Liquid

Color Brown

Odor Slight fermentation odor Enzymatic Activity ≥20,000 u/Ml Solubility Soluble in water

Benefit

Complete removal of residual H2O2 in preparation for dyeing Wide pH range, convenient in using

No damage of fabric Reduced processing time Reduced water consumption and effluent volume Few dosage

Environmental-friendly & bio-degradation

Properties

Effective temperation:20-60℃, optimum temperation: 40-55℃ Effective PH: 5.0-9.5,optimum PH:6.0-8.0

Application

In textile industry, Catalase can remove the residual hydrogen peroxide after bleaching, shorten the process, save energy, water and reduce the pollution for the environment.

In food and fresh milk industry, the recommended dosage is 50-150ml/t fresh raw material at 30-45℃ for 10-30mins, no need to adjust pH.

In beer storage and sodium gluconate industry, the recommended dosage is 20-100ml/t beer at room temperature in beer industry. The recommended dosage is 2000-6000ml/t dry matter with concentration 30-35% pH about 5.5 at 30-55℃ for 30 hours.

In Pulping and papermaking industry, the recommended dosage is 100-300ml/t bone dry pulp at 40-60℃ for 30 minutes, no need to adjust pH.

Package and Storage

Plastic drum is used in liquid type.

Should be stored in a dry place with temperature between 5-35℃.

Notice

The above information and the conclusion obtained is based on our current knowledge and experience, users should be according to the practical application of different conditions and occasions to determine the optimal dosage and process.